UV curing

UV Curing

UV curing is a process in which ultraviolet light and visible light is used to initiate a photochemical reaction that generates a crosslinked network of polymers.

Our UV curing module is not a stand-alone module, it is part of a UV curing machine assembled by the customer.

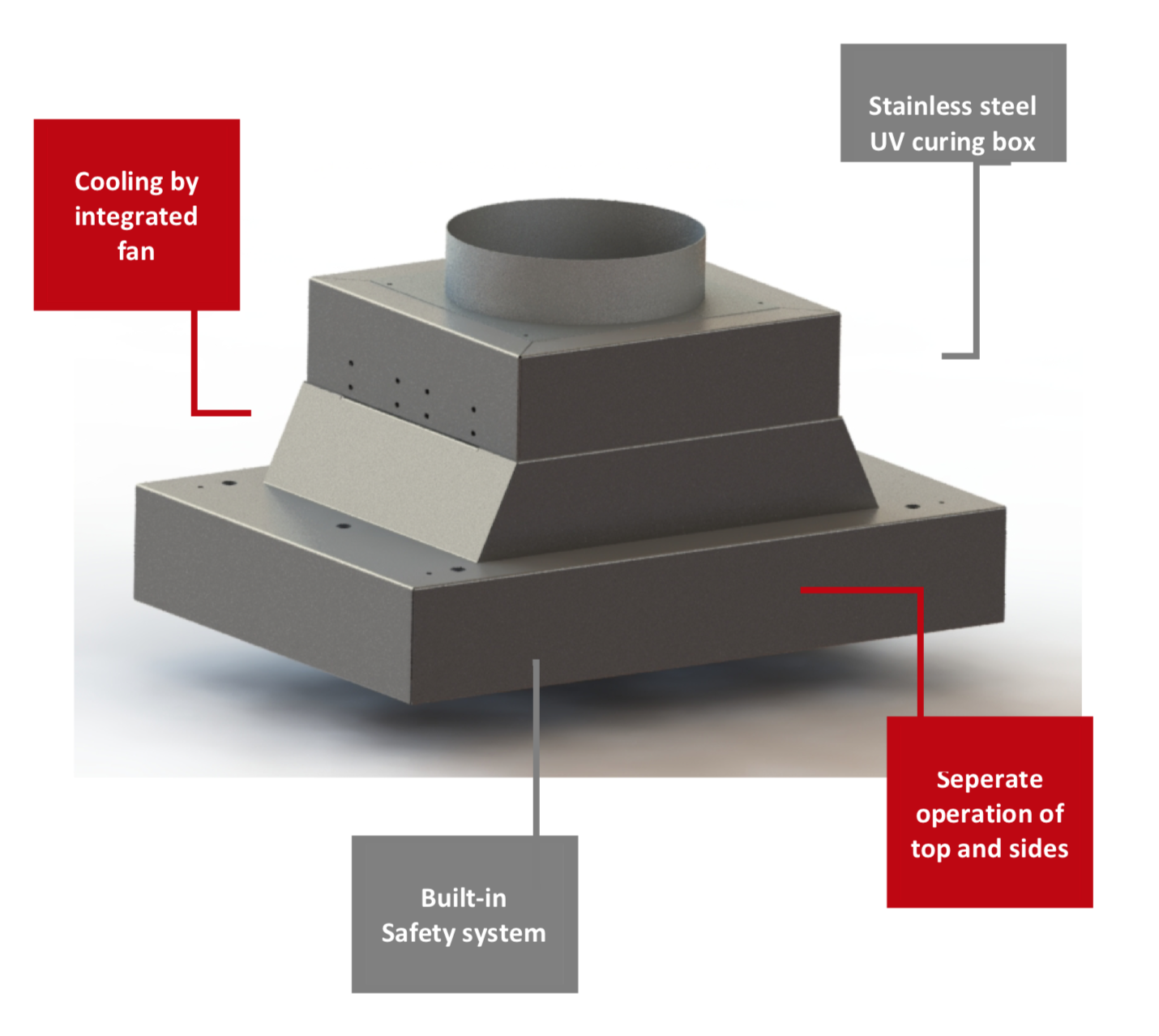

UV Curing module

The module consists of the following components:

- Stainless steel UV Curing Box

- Power Cabinet

- Cable Harness consisting out of 2 LED control cables

- Temperature control

- Fan Power

In the stainless-steel UV curing box, the UV power is generated from the top.

The LEDs are equally distributed over the surface which makes it homogeneous. At maximum current setting (500mA) this will generate 600mW/cm2 at a distance of 30 mm approximately.

The side PCBs are divided in two sections for different purposes;

larger and smaller products.

- The top three rows of a side PCB; This section is for the larger product, e.g. >15”. At maximum current setting (500mA) the output is approximately 200mW/cm2 at a distance of 30mm.

- The bottom rows of this side PCB; These lenses narrow the UV power to a smaller beam to be able to have enough power at larger distances, for smaller products. Output at maximum current (500mA) is approximately 200mW/cm2 at a distance of 80mm.

Everything under control

The top and two side sections can be controlled separately. In normal operation the top section will be combined, depending on the display size.

Safe

The cooling of the UV curing box is done by one radial fan and the system is protected by a built-in safety system.

The primary advantage of curing finishes and inks with ultraviolet lie in the speed at which the final product can be readied for shipping. In addition to speeding up production, this also can reduce flaws and errors, as the amount of time that dust, flies or any airborne object has to settle upon the object is reduced. This can increase the quality of the finished item and allow for greater consistency.

Environmentally friendly

UV LED curing units are environmentally friendly and have a much greater energy efficiency than traditional UV lamps.

And ….

They also have significantly lower operating temperatures and longer operating lifetimes.

Leemstraat 40-44, 4705 RH Roosendaal, The Netherlands

Leemstraat 40-44, 4705 RH Roosendaal, The Netherlands